Lithium Densifier

Product Details:

- Physical Form Liquid

- Color Colorless

- Grade Industrial

- Type Concentrated & premium nano-lithium based

- Usage It is safer, faster and easier to apply. It penetrates deep in the concrete to produce insoluble calcium silicate hydrate within the concrete pores. The increased surface hardness imparted by LD drastically improves abrasion resistance, reduces liquid penetration and dusting and simplifies maintenance.

- Ph Level Alkaline

- Application It is safer, faster and easier to apply. It penetrates deep in the concrete to produce insoluble calcium silicate hydrate within the concrete pores. The increased surface hardness imparted by LD drastically improves abrasion resistance, reduces liquid penetration and dusting and simplifies maintenance.

- Click to View more

Lithium Densifier Price And Quantity

- 20 Kilograms

- 300 INR/Kilograms

Lithium Densifier Product Specifications

- 28399090

- Alkaline

- It is safer, faster and easier to apply. It penetrates deep in the concrete to produce insoluble calcium silicate hydrate within the concrete pores. The increased surface hardness imparted by LD drastically improves abrasion resistance, reduces liquid penetration and dusting and simplifies maintenance.

- It is safer, faster and easier to apply. It penetrates deep in the concrete to produce insoluble calcium silicate hydrate within the concrete pores. The increased surface hardness imparted by LD drastically improves abrasion resistance, reduces liquid penetration and dusting and simplifies maintenance.

- Industrial

- Colorless

- Concentrated & premium nano-lithium based

- Liquid

Lithium Densifier Trade Information

- JNPT Nava Shewa, India

- Letter of Credit at Sight (Sight L/C)

- 20000 Kilograms Per Week

- 1 Week

- Yes

- Free samples available with shipping and taxes paid by the buyer

- 60 kg carbuoy and 250 kg plastic drum

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO 9001:2015

Product Description

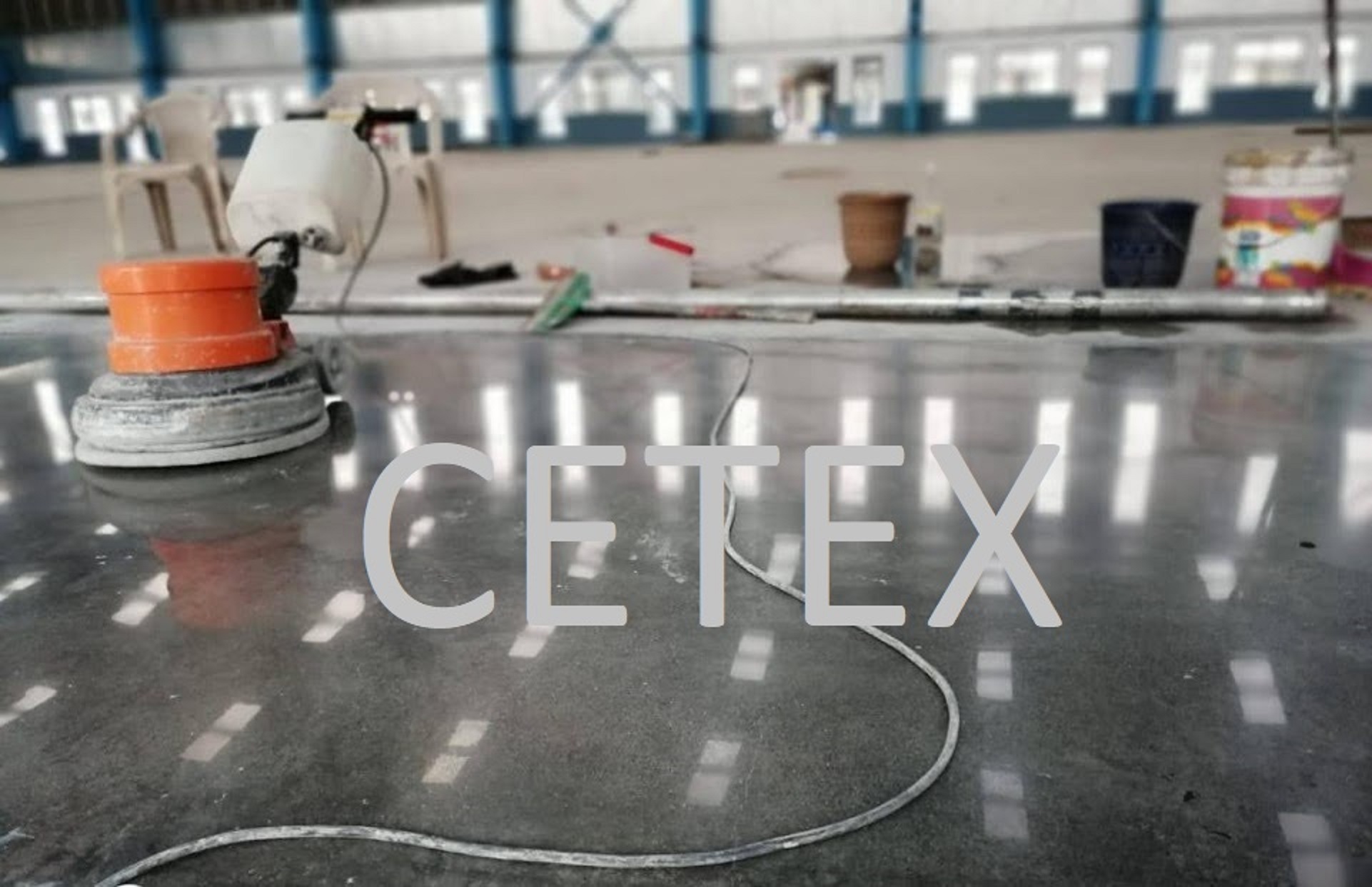

CETEXLDis concentrated & premium nano-lithium based densifier, hardener for cementatious surfaces. It is safer, faster and easier toapply. It penetrates deep in the concrete to produce insoluble calcium silicatehydrate within the concrete pores. The increased surface hardness imparted byLD drastically improves abrasion resistance, reduces liquid penetration anddusting and simplifies maintenance.

ADVANTAGES

- No scrubbing. No flushing. No wastewater.

- By reducing the pores of the surface, it aids in curing of green concrete.

- Can be applied on any uncoated concrete or mortar finishes in both new as well as old constructions.

- Treated surface is breathable, but seals micro-channels against chemical attack that cause corrosion.

- Helps reduce damaging alkali-silica reactions ASR and protects from weathering and efflorescence.

- Penetrates deep into the surface to improve hardness, compressive and flexural strength of surface.

- Provides better abrasion resistance than conventional hardeners.

- Reduces application time and costs of diamond polishing operations.

- Though it improves gloss and hardness, it does not reduce slip resistance.

- Treated surface is breathable, UV stable and maintains natural appearance.

- Produces a fast permanent surface gloss which improves with traffic and maintenance.

- Makes the surface better looking and dust-proof. Will not yellow, discolour, peel or flake.

- Cures quickly. Treated surface can be used within one hour of treatment.

- VOC content is nil, thus helps earning LEED points in green building.

- It is concentrated. Hence economical for transport. Non-flammable. Non-toxic.

- Reduces maintenance, cleaning costs andrepairs. It is economical to use.

PROPERTIES

TotalSolids Content 24 percent approx.

SpecificGravity at 25Degree C 1.20

pH Alkaline

VOCContent Nil

Application Methods

Clean the surface before application. If there is coating on the surface, for example curing compound, oil, dust etc., it should be removed. Fill and repair all holes, cracks and deteriorated areas. For best result, the surface should be dry to touch to allow diluted LD penetrate the pores and react.LD is concentrated material and can be diluted with 1-3 parts of soft water for every one part of LD. It can be applied on old or new clean surface by using a low-pressure sprayer, roller or brush.

For Horizontal surfaces, apply enough diluted LD to keep the surface wet for 20 minutes. If areas dry out before that, apply more diluted LD. In hot, dry or windy conditions dampen concrete before application to prevent flash drying. Remove any dried powder residue using a stiff broom, power sweeper or floor scrubbing machine. For immediate, enhanced shine, buff or burnish the dry concrete surface in both directions using an orbital floor machine or burnisher equipped with an appropriate polishing pad. This is a dry buffing operation.

For vertical surfaces, apply from the bottom up. For maximum penetration and desired coverage rates, a wet-on-wet application is recommended; re-treat within three to five minutes after initial application. Repeated applications should be made until the surface remains moist for a minute or so before solution disappears.

PACKING

CETEX LD is available in 60 kg carbuoyand 250 kg plastic drum.

STORAGE

When stored in anairtight, sealed container in normal conditions has a shelf life of 12 monthsfrom date of shipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Hardeners & Densifiers' category

|

XETEX INDUSTRIES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free